While many people probably consider scooters to just be small motorcycles, scooters and motorcycles are actually quite different in a few key ways. The frames used by scooters are completely different from the ones used by motorcycles, as are the transmissions they use.

In this article, we’ll be talking all about scooter transmissions, including what kind of transmissions scooters actually use, how scooter transmissions work, and how exactly scooter transmissions are different from motorcycle transmissions.

What Kind of Transmissions Do Scooters Use?

The biggest difference between scooters and motorcycles (in terms of what transmissions they use) is that almost every modern scooter uses an automatic transmission while almost every motorcycle uses a manual transmission.

Specifically, scooters use what’s called a continuously variable transmission (CVT) which is an automatic transmission that has no gears and no shifting required.

The whole point of scooters is to be comfortable, simple, and easy to ride, and that’s probably the main reason why most scooter manufacturers have opted to use automatic transmissions instead of manual ones.

Not having to actively shift gears yourself certainly simplifies the driving experience and makes riding a scooter way more accessible.

Plus, two-wheeled vehicles usually need to have foot-operated manual transmissions, but automatic scooters means that the space that would otherwise be taken up by transmission controls can now be used as a footrest. This is another feature that helps scooters be a bit more comfortable than motorcycles.

How Does CVT Work?

Let’s talk about how the automatic transmission in a scooter actually works. As we’ve mentioned, most scooters use a specific type of automatic transmission called a Continuous Variable Transmissions.

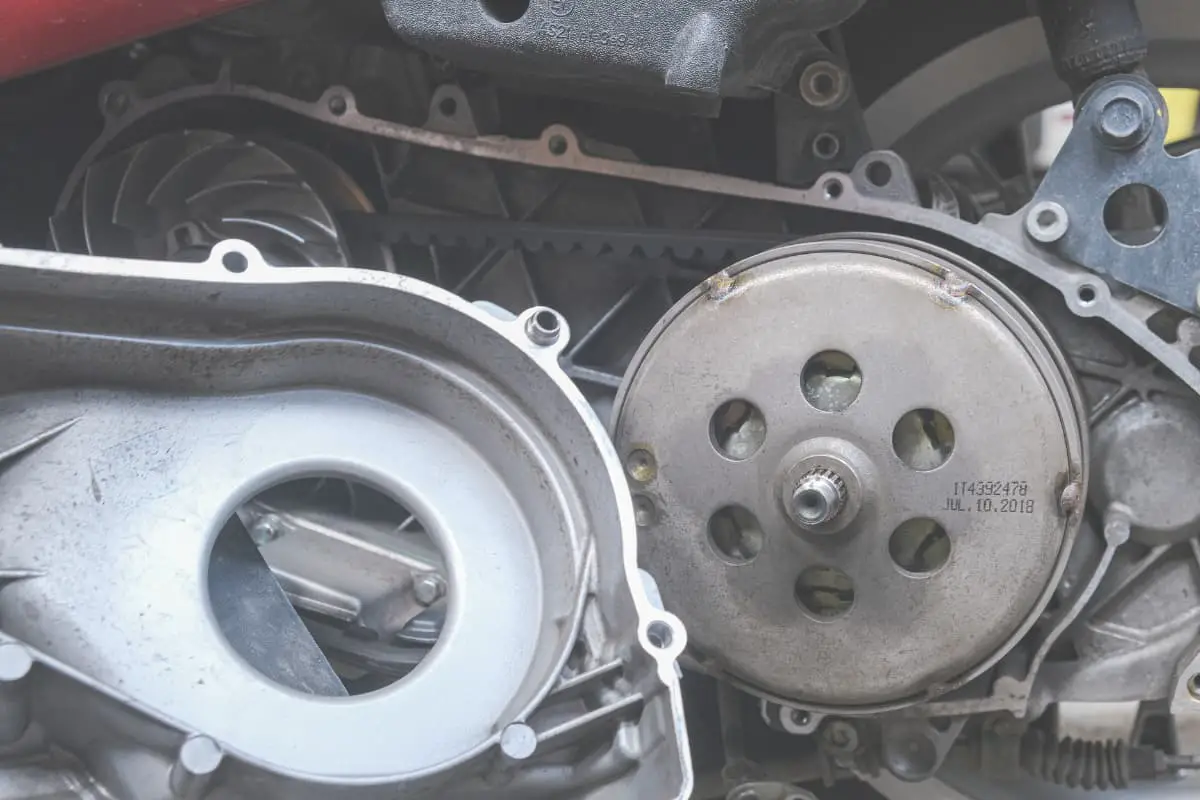

A CVT is different from other transmissions in that it doesn’t use separate gears to create different gear ratios. Instead, the CVT in a scooter consists of two pulleys connected by a v-belt. One of these pulleys is connected to the engine, while the other is connected to the scooter’s driven wheel.

Scooters with a Continuous Variable Transmission do not have gears but 2 pulleys and a connecting belt.

Each pulley in a CVT consists of two conical pieces that face toward each other. The belt connecting the pulleys sits in between these conical pieces. To adjust the gear ratio, the CVT moves these conical pieces closer or farther apart from each other.

Since the v-belt rides on the slopes of the pulley cones, this means that pushing the cones together effectively creates a larger diameter pulley while pulling them apart creates a smaller pulley.

Depending on whether the drive pulley or the driven pulley (attached to the rear wheel) has a larger diameter, this can allow the engine to either run at a higher engine RPM or deliver more torque.

CVTs have a range of gear ratios as determined by the maximum and minimum diameter of the pulleys, but within this range, there is a near-infinite number of gear ratios.

This is because the design of a CVT allows the transmission to make minute adjustments to any given ratio by slightly increasing or decreasing the diameter of the pulleys and rollers for the centrifugal clutch.

Here’s a video to help illustrate the process, but Dual Wheel Journey talks about this on a podcast if you want to hear more about the CVT Transmission on the go.

Pros and Cons of CVTs

To be fair, CVTs are probably the best kind of transmission to use in something like a scooter, as we’ll discuss shortly. However, CVTs aren’t perfect transmissions overall, and certainly have their share of drawbacks.

Let’s take a minute to go over the advantages and drawbacks of CVTs compared to conventional automatic transmissions:

Advantages

The biggest advantage that CVTs have over conventional automatics is their improved fuel economy. Because the gear ratios in a CVT can be almost infinitely adjusted, this allows the engine to run as efficiently as possible regardless of what speed it’s running at.

CVTs are also a lot lighter than conventional automatics thanks to the fact that they contain fewer overall parts. Their low weight is another feature that helps improve fuel economy in vehicles that use them since the engine obviously has less weight to lug around.

Also because of the near-infinite gear ratios in a CVT, a vehicle that uses one is usually a lot more responsive when the gas pedal is pressed. This is due to the lack of distinct gears; because a CVT can adjust its gear ratio on the fly, it can pretty much always be instantly in the right “gear” for any driving situation.

Another advantage of CVTs is how smooth they are to operate. Again, because CVTs work by adjusting the distance between the two halves of the pulley rather than switching connections between multiple gears, this means that gearshifts don’t actually happen in a CVT.

Because of their small size and the fact that they’re intended to be ridden easily, it’s pretty clear to see why CVTs are the ideal transmission for most scooters.

Disadvantages

Of course, no technology is perfect, and CVTs are no exception. Probably the biggest drawback of CVTs has to do with their durability and maintenance costs.

While CVTs aren’t unreliable as such, they do tend to wear out a little faster than conventional automatic transmissions. This is because the parts in a CVT move around and come into contact with each other more often than the parts in a conventional automatic, so the components inside can sometimes degrade more quickly.

One of the most common complaints concerning CVTs is the noise they make when accelerating. Because of how CVTs work, the engine has to run at a comparatively high rpm to get the vehicle moving from a standstill. While this is more of an annoyance than an actual drawback, it’s definitely been enough to somewhat hamper the popularity of CVTs.

This isn’t really an issue with scooters, as all scooters are pretty small and lightweight, but CVTs don’t work very well in large, heavy vehicles. The belts and pulleys in a CVT that transmit power aren’t strong enough to handle the weight and torque demands that such vehicles have.

As such, not only are CVTs not great for large vehicles, but they’re also not great for towing anything either. Again, they’re just not really capable of handling the amount of torque needed for effective towing.

Finally, one of the main disadvantages of CVTs is that they’re often more expensive to repair than conventional automatics despite having fewer parts. This is because the parts themselves in a CVT are more costly to replace than the parts in a conventional automatic. CVTs are also less common, so it can be harder to find someone who actually knows how to work on them.

How Does a Motorcycle Transmission Work?

At this point, you might be wondering how exactly the transmission in a motorcycle works compared to the transmission in a scooter. As you can probably guess, the differences are pretty significant.

The vast majority of motorcycles use manual transmissions, specifically sequential manual transmissions. Aside from motorcycles, it’s pretty rare to see sequential transmissions used in any regular commuter vehicles; sequential manuals are usually used only by race cars.

In this kind of manual transmission, “sequential” refers to the fact that the rider can only shift directly up or down from the gear they’re already in. This is in contrast with other manual transmissions, where you can shift through the gears in whatever order you want (for example, you could go directly from 1st gear to 4th in a normal manual transmission).

Motorcycles use sequential manuals because the design of a motorcycle doesn’t really leave options for anything else. Your hands are already occupied by the throttle and brakes when you’re on a motorcycle, so it’s not really possible to make complex gear changes like you can in a car.

CVT Maintenance

The CVT have different maintenance schedules depending on the brand of scooter it seems. Before I dive into a bit more on the maintenance, just know that the irony is not lost on me when I see that something requires gear oil even though an automatic scooter does not have gears!

But remember, I’m trying to keep this high level assuming you don’t have a mechanical background, but other part names that might be helpful would be that it can also be referred to as the drive train.

Other parts & a quick description are below from front to back, outer to inner, but if this list intimidates you, your local scooter shop will set you right!

- The driver/driven pulleys may also be referred to as front & rear pulleys.

- Front/driver pulley: includes variator, outer front pulley half & rollers & gets the power from the engine through this section.

- Outer front pulley: Outer part that is fixed to the engine & turns

- Variator assembly: Includes the moving pulley half, rollers & a cover plate + bushings to keep things where they need to be. Slides along the shaft in relation to how much the engine is putting out (i.e. your hand on that throttle!)

- Rollers: sometimes uses sliders instead

- Drive belt: connects the pulleys & while stays 1 size, varies based on the pulley assemblies to the higher or lower RPM to torque ratio

- Driven Pulley: aka rear pulley & this area contains the clutch bell, clutch mechanism, torque controller and a contraspring.

- Clutch assembly: Clutch plates & springs & bell. Turns the rear wheel

Below are the intervals in the schedule maintenance of the scooter manuals on deck.

Vespa GTS 300 HPE

- CVT filter: checked every 6,200 miles & replaced as needed

- Sliding shoes / CVT Rollers: replace every 6,200 miles

2020 Genuine Scooters Buddy Kick

- CVT Filter: cleaned or replaced every 1,875 miles (or every 3 months)

- Gear Oil: First 500 miles & every 1,875 beyond

2019 Kymco Like 150i

- Transmission Oil: Replace at 600 miles & every 4,500 miles beyond

- Drive Belt: inspect every 3,000 miles & replace at ~12,000 miles

- CVT filter: cleaned every 3,000 miles

Those are the manufacture requirements, and I don’t recommend you deviate from them for your warranty’s sake.

However, I live with a mechanic, and the maintenance we do involves checking the oil color and such. We’ll also wait until there is a visible need to replace any belt for drying or cracking evidence.

If you have more high level questions, I highly recommend you sign up for the email list. I send out some behind the scenes, share scooter fun things, and I reply to emails!

![Scooter Rain Gear Essentials [Stay Happy & Dry]](https://scootersfornewbies.com/wp-content/uploads/2022/01/rain-drops-on-vespa-side-mirror-768x512.jpg)